大昌華嘉科學儀器部

白金會員

白金會員 已認證

已認證

大昌華嘉科學儀器部

白金會員

白金會員 已認證

已認證

Highlighting reproducibility & Comparison vs Flodex

再現性&Flodex的比較

Introduction

介紹

Theoretical Framework

理論概況

Granular materials and fine powders are widely used in industrial applications. To control and to optimize processing methods, these materials have to be precisely characterized. The characterization methods are related either to the properties of the grains (granulometry, morphology, chemical composition, …) and to the behaviour of the bulk powder (flowability, density, blend stability, electrostatic properties, …). However, concerning the physical behaviour of bulk powder, most of the techniques used in R&D or quality control laboratories are based on old measurement techniques. During the last decade, we have updated these techniques to meet the present requirements of R&D laboratories and production departments. In particular, the measurement processes have been automatized and rigorous initialization methods have been developed to obtain reproducible and interpretable results. Moreover, the use of image analysis techniques improves the measurements precision.

顆粒狀材料和精細粉體在工業上有著廣泛的應用。為了控制和優化加工方法,必須對這些材料進行精確的表征。表征方法既與顆粒的性質(粒度、形態、化學成分等)有關,也與粉體的行為(流動性、密度、共混穩定性、靜電性能等)有關。然而,關于散裝粉末的物理性能,大多數在研發或質量控制實驗室使用的技術是基于舊的測量技術。在過去的十年中,我們更新了這些技術,以滿足研發實驗室和生產部門目前的要求。特別是,測量過程已經自動化,并開發了嚴格的初始化方法,以獲得可重復和可解釋的結果。利用圖像分析技術提高了測量精度。

A range of measurement methods has been developed to cover all the needs of industries processing powders and granular materials. However, in this application note, we will be focused on the GranuFlow instrument.

一系列的測量方法已經發展,以涵蓋所有的需要,工業加工粉末和顆粒材料。但是,在這個應用說明中,我們將主要關注GranuFlow儀器。

GranuFlow

粉體流動性分析儀

GranuFlow is an improved laboratory silo compared to the ancient Hall Flow Meter (ASTM B213, ISO4490) and compared to the “Flow Through An Orifice” method described in the Pharmacopeia (USP1174).

與古老的霍爾流量計(ASTM B213, ISO4490) 或者與藥典(USP1174)中描述的“通過孔口的流動”方法相比,GranuFlow是一個先進的流速計。

GranuFlow is a straightforward powder flowability measurement device composed of a silo with different apertures associated with a dedicated electronic balance to measure the flowrate. This flowrate is computed automatically from the slope of the mass temporal evolution measured with the balance. The aperture size is modified quickly and easily with an original rotating system. The measurement and the result analysis are assisted by software. The flowrate is measured for a set of aperture sizes to obtain a flow curve. Finally, the whole flow curve is fitted with the well-known Beverloo theoretical model to obtain a flowability index (Cb, related to the powder flowability) and the minimum aperture size to obtain a flow (Dmin) (for theoretical background, user can refer to Appendix 1). The whole measurement is performed easily, fastly and precisely.

GranuFlow是一種簡單明了的粉末流動性測量裝置,它由一個不同孔徑的筒倉和一個專用的電子天平組成。這種流量是根據用天平測量的流速質量隨時間演化的比率(斜率)自動計算出來的。利用原有的旋轉系統,可以快速、方便地調整孔徑大小。軟件輔助測量和結果分析。通過測量一組孔徑尺寸來獲得流量曲線。最后,整個流動曲線是配備知名Beverloo理論模型獲得流動性指數(Cb、粉末流動性相關)和最小孔徑大小獲得流(Dmin)(為理論背景,用戶可以參考附錄1)。整個測量容易執行,快速準確。

In this paper, we used a complete set of hole diameters: 4, 6, 8, 10, 12, 14mm and 16mm.

在本文中,我們使用了一套完整的孔徑:4、6、8、10、12、14和16毫米。

The main purpose of this application note is to provide information about the measurements reproducibility with the GranuFlow and to show some examples about what is it able to offer. In a second part, a comparison between Hall Flowmeter and GranuFlow is presented in order to show the advantage of using GranuFlow.

本應用說明的主要目的是為醫藥領域提供有關乳糖分析的信息。

Experimental setup

實驗方法

Material

材料

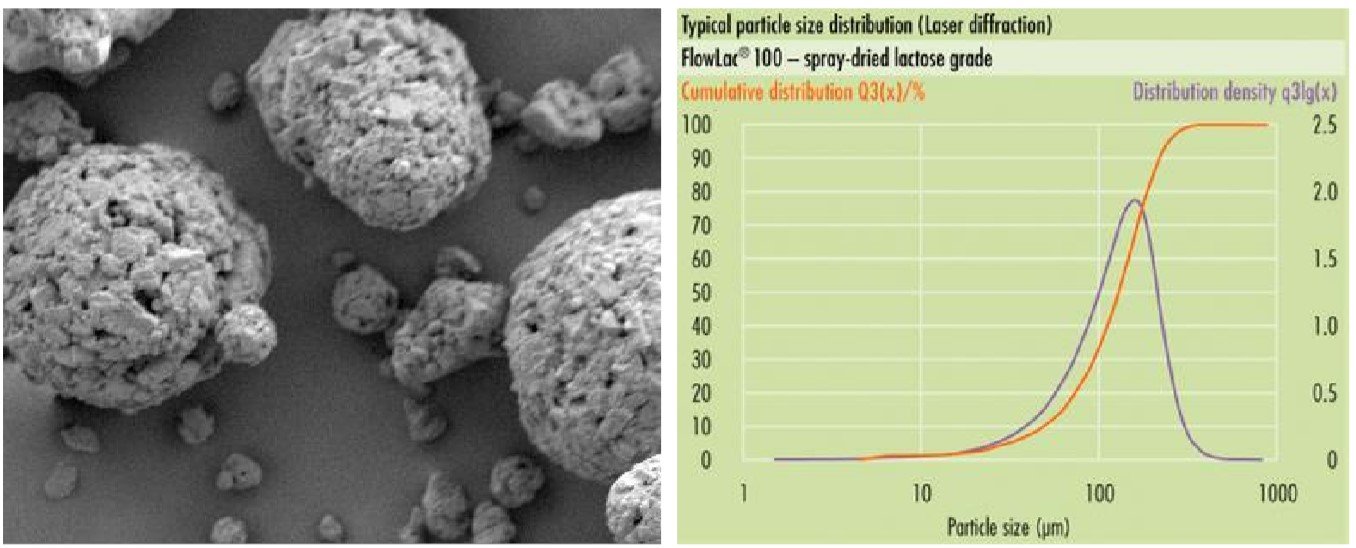

The product FlowLac 100 provided by Meggle Pharma is used in this application note. It is produced by spray-drying a suspension of fine milled alpha-lactose monohydrate crystals in a solution of lactose. When lactose in solution is spray-dried, a rapid removal of water is taking place, whereby amorphous, non-crystalline lactose is formed in addition to crystalline lactose.

Meggle Pharma提供的產品FlowLac 100用于本案例。它是通過噴霧干燥懸浮液的精細研磨阿爾法乳糖一水晶體在乳糖的解決方案。當溶液中的乳糖被噴霧干燥時,水的快速去除就發生了,因此除了結晶乳糖外,無定形的、非晶狀的乳糖也形成了。

Due to the spray-drying process, this powder has a spherical shape, consisting of small alphalactose monohydrate crystals bound by amorphous lactose.

由于噴霧干燥過程,這種粉末有一個球形的形狀,由無定形乳糖結合的小無定型乳糖晶體組成。

Figure 1: FlowLac 100, SEM Picture and particle size distribution (manufacturer data).

圖1:FlowLac 100, SEM圖片和粒度分布(生產商數據)。

Experimental protocol

實驗方案

GranuFlow

粉體流動性分析儀

GranuFlow analysis were performed at 20.6°C and 34.6%RH. Mass Flowrate was investigated for different hole size (from 4mm to 16mm). Measurements were repeated three times

在20.6℃和34.6%RH下使用GranuFlow分析。研究了不同孔徑(4mm ~ 16mm)下的質量流量。測量重復三次

F is the powder flowrate (in g/s) and Cb the Beverloo parameter (in g/cm3). Dmin is the minimum aperture size to obtain a flow (for more information about the Beverloo model, please refer to Appendix 1).

F為粉末流量(單位為g/s), Cb為Beverloo參數(單位為g/cm3)。Dmin是獲得流的最小孔徑大小(有關Beverloo模型的更多信息,請參見附錄1)。

5 min are needed to run one complete measurements (with every hole size, cleaning and with Beverloo’s Law calculation).

需要5分鐘來完成一次完整的測量(每個孔的大小,清洗和貝弗羅定律計算)。

Flodex

Flodex analysis were performed at 21.2°C and 34.3%RH. Mass flowrate was measured for the same aperture size than those used with the GranuFlow (from 4 to 16mm). Measurements were repeated two times.

在21.2℃和34.3%RH下使用Flodex進行分析。在孔徑尺寸相同(4 - 16mm)的情況下測量質量流量。測量重復兩次。

30 min are needed to run all measurements (with every hole size, cleaning, but without plotting the Beverloo’s Law).

需要30分鐘來運行所有的測量(每個孔的大小,清潔,但不繪制貝弗里洛定律)。

GranuFlow versus Flodex

GranuFlow對比Flodex

Experimental results

實驗結果

The following figure allows comparison between GranuFlow and Flodex. All error bars are calculated using the standard deviation obtained for reproducibility measurements (S is the average sum of squared residuals, calculated with the experimental and Beverloo mass flowrates). The flowability of FlowLac 100 powder was investigated three times with the GranuFlow and two times with the Flodex:

下圖比較了GranuFlow和Flodex。所有的誤差條都是用可重現性測量得到的標準偏差來計算的(S是殘差平方和的平均值,用實驗和貝弗盧質量流量來計算)。對FlowLac 100粉體的流動性進行了3次GranuFlow實驗和2次Flodex實驗:

Figure 2: Mass flowrate versus aperture size - Comparison between GranuFlow and Flodex.

圖2:質量流量與孔徑大小- GranuFlow對比Flodex

The first observation is related to the ease of use of the GranuFlow in comparison with Flodex. Indeed, many time is wasted to change Flodex’s disks and to clean all the workplan between two experiments. Moreover, Flodex instrument does not allow the Beverloo law determination (calculations were done after experiment using the excel software).

第一個觀察結果是與Flodex相比,GranuFlow更容易使用。事實上,在兩次實驗之間,許多時間被浪費在更換Flodex的轉盤和清洗上。此外,Flodex儀器不符合的測定(計算是在使用excel軟件進行實驗后進行的)。

Regarding the average sum of squared residuals, it is possible to conclude that the Beverloo law regression is more accurate with the GranuFlow (S = 2.70g2/s2) than the Flodex instrument (S = 9.99g2/s2).

關于平均殘差平方和,可以得出這樣的結論: 對于貝弗盧定律計算,GranuFlow (S2= 2.70 g / S2)比Flodex儀器(S2= 9.99 g / S2)更準確。

If we consider the error bars (especially with an aperture of 16mm), we can see that the reproducibility is better with GranuFlow than Flodex. This fact is explained by the complete automatic procedure for the GranuFlow, while the time measurement is achieved manually (chronometer) with the Flodex instrument.

如果我們考慮誤差條(特別是孔徑為16mm的),我們可以看到,GranuFlow的重現性比Flodex更好。這一事實是解釋了具備完整自動檢測程序的GranuFlow的優勢,而Flodex則只能通過使用(精密計時器)實現手動計時。

Finally, GranuFlow and Flodex result are slightly different, some issues with the Flodex instrument may explain this fact: powder aeration/electrostatic charges during measurement and porous medium height dependency.

最后,GranuFlow和Flodex的結果略有不同,Flodex儀器的一些問題可以解釋這一事實:在測量過程中粉末的透氣/靜電荷和多孔介質的高度相關性。

Flodex issues

Flodex問題

Triboelectricity and powder aeration

靜電和粉體透氣性

For the Flodex experiment, the powder is used to analyse mass flowrate versus aperture size. However, despite this protocol allows to use a small powder quantity, it also leads to electrical charges build up inside the powder (cf. Figure 3). Therefore, at the end of experiment the powder mass flowrate will be erratic.

在Flodex實驗中,粉末用于分析質量流量與孔徑大小的關系。然而,盡管該方案允許使用少量粉末,但也會導致粉末內部電荷積聚(cf.圖3),因此,在實驗結束時,粉末的質量流量將不穩定。

Figure 3: Beaker photography after experiments with Flodex - Highlighting the electrostatic effect.

圖3:用Flodex做實驗后的燒杯照片——靜電效果。

Moreover, using the same powder will aerate it, and therefore, it will modify the powder flowing behaviour.

此外,使用相同的粉末會使空氣進入粉體,因此,它會改變粉末的流動行為。

Powder height dependency

粉體高度依賴性

Contrary to the fluids, when a silo is discharged by gravity, the flow rate does not depend on the height of the granular layer. Indeed, when this value is greater than 1.2 times the diameter of the silo, the pressure at the bottom of the silo saturates due to the Janssen effect and hence, the flow rate remains constant (Mankoc et al., 2007).

與流體相反,當筒倉在重力作用下排出時,其流速并不取決于顆粒層的高度。實際上,當該值大于筒倉直徑的1.2倍時,筒倉底部的壓力由于Janssen效應而飽和,因此流量保持不變(Mankoc et al., 2007)。

However, due to the small height of the Flodex instrument (7.5cm), the powder height dependency is still observed at the end of its tank discharge. Thus, this instrument will be only useful to have an idea about the minimum aperture for the powder to flow.

然而,由于Flodex儀器的高度較小(7.5cm),在其容器排放結束時仍能觀察到粉末高度依賴性。因此,這個儀器只有在知道粉末流動的最小孔徑時才有用。

Conclusions

結論

? An experiment with the GranuFlow is extremely faster than Flodex (5min with GranuFlow and 30min with Flodex).

使用GranuFlow的實驗速度比Flodex快得多(5分鐘使用顆粒劑,30分鐘使用Flodex)。

? GranuFlow allows to plot the full Beverloo mass flowrate curve, while Flodex only allow experimental data measurements.

GranuFlow能夠繪制完整的Beverloo質量流量曲線,而Flodex只能夠給出實驗數據。

? GranuFlow provides powder flowability measurements with Beverloo Law (i.e. Cb coefficient, with an error close to 2.4%) and an estimation of the Cohesive Index with Dmin parameter (minimum diameter for the powder to flow in silo configuration).

GranuFlow使用貝弗羅定律(即Cb系數,誤差接近2.4%)對粉末流動性進行測量,并使用Dmin參數(粉末在筒倉結構中流動的最小直徑)估計粘性指數。

? However, Flodex provides powder flowability with a slightly worse accuracy (3.1%), and no information about the Beverloo law is given (calculation need to be carried out with excel).

但是,Flodex提供的粉末流動性準確性稍差(3.1%),而且沒有給出貝弗里洛定律(Beverloo law)的信息(需要用excel進行計算)。

Bibliography

參考文獻

Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

Appendix 1: GranuFlow theoretical background

附錄1:GranuFlow理論背景

The mass flowrate F through a circular orifice of diameter D is given by the product of the mean speed of the grains

質量流率F通過圓孔的直徑D的產物顆粒的平均速度<流出速度>、孔徑面積和體積密度ρ。一個是一般表達式:

相關產品

更多

相關文章

更多

技術文章

2024-10-09技術文章

2024-08-10技術文章

2024-05-30技術文章

2024-05-30

虛擬號將在 秒后失效

使用微信掃碼撥號